PET bottle blowing technology, Nuo Guan has made another "big move"!

?

Today, Professor Nuo will reveal the story behind the bottles.

Strongly interpret Nuo Guan's PET linear machine and rotary machine industry solutions.

Beautiful、Strong、Save

From the production process, before consumers drink a certain beverage, the product "beverage" needs to go through: injection molding, blow molding,

canning, sealing, labeling, coding, packaging, stacking and storage processes. Nuo Guan can provide integrated solutions for the entire process, today

let's focus on blow molding. So how does a bottle preform turn into a bottle?

The blow molding process - done with a puff!

Blow molding module

Increase capacity and efficiency

Nuo Guan's rich experience in the PET industry for over 30 years and its patented piston technology enable us to help customers save energy consumption and improve equipment performance,

as well as increase capacity and efficiency.

Beautiful Optimized control

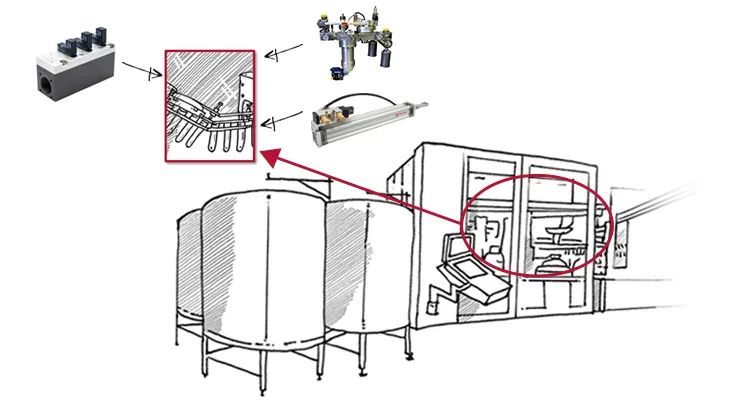

Integrating multiple functions, including pre-blow valve, middle blow valve, final blow valve, exhaust valve, compensation valve, sealing cylinder and other control valves, through different combinations and configurations of these products, we can provide you with diverse, flexible, and cost-effective solutions.

Higher capacity

Strong Nuo Guan's products and technical support have currently achieved a blow molding speed of single cavity bottles per hour, helping you maximize capacity and enhance

core performance.2800Lower cost

Our rich gas recovery management technology combined with continuously optimized product minimum dead volume standards means we can maximize energy savings for your equipment,

Save and improve efficiency.

How can we help enterprises better reduce costs?

Gas supply unit and air recovery system

Large flow, precise control, and reliable performance

Nuo Guan provides a complete set of pneumatic products, from standard products at 7bar to 20bar pre-blow (P1), to 40bar forming blow (P2), regardless of your requirements for size, capacity, or flow,

with our expertise in the food and beverage industry, we can ensure reliability, and the unique modular design allows for plug-and-play, making replacements quick

and cost-effective.

Nuo Guan advantages

Cost savings

The complete air recovery of the 7bar~28bar production line helps you improve air usage efficiency.

The complete air recovery of the 7bar~28bar production line helps you improve air usage efficiency.

Fully compatible

Our technology helps you achieve precise pressure regulation.

Flexibility

The compact, universal, and plug-and-play features allow the system to adapt to various needs.

Increase output

We can provide high-flow products to help you increase the maximum capacity of bottles.

Pressure proportional valve

This technology allows you to achieve remote and rapid precise pressure adjustment, making operations safer and more reliable.

For over thirty years, Nuo Guan has been committed to meeting the unique needs of the global food and beverage industry, providing innovative products and customized solutions. We work closely with customers, achieving remarkable achievements in helping large-scale food companies around the world improve efficiency, save energy, and optimize performance.

Quality excellence leads to long-term cooperation.

Nuo Guan is your trusted breakthrough engineering technology partner.

.品质卓越所以合作长

久,诺冠是您可信赖的突破性工程技术合作伙伴。

Related News

What impact does the F011068 Norgren valve group pilot valve have?

2022-12-23 11:19

What is the function of the 191.019.01 Saichi SEITZ pilot valve?

2022-09-20 13:37